Smart Cashmere

Smart Green Products--------Coarse woven cashmere fabric "follows the path of green development and creates a harmonious and win-win plan

Green product functions

After spinning, weaving, dyeing and finishing of cashmere wool raw materials, the fabric produced not only has the specific properties of wool cashmere fabric, but also has the functions of being delicate, soft, and safe to wear. This product has been released as a T/ZZB0783-2018 group standard in "Made in Zhejiang". Contains 30% wool cashmere fabric to 100% cashmere fabric, used in the manufacturing of clothing and apparel. The product is mainly provided to mid to high-end consumers to meet the needs of some consumers for cashmere products. Using cashmere and wool that meet China's health and epidemic prevention requirements as raw materials, the products produced have the rigidity of wool, the luster and feel of cashmere, which not only have a warm effect, but also have a high-end and atmospheric style of cashmere.

Cashmere products are known as "soft gold" and "fiber queen" in the industry, and are increasingly favored by mid to high-end consumers. During the production process, this product undergoes careful design and production in the early stage, followed by a unique process of post-processing, resulting in a plush and plump appearance, a glossy and elegant appearance, a smooth and soft texture, and high-quality wearing performance.

SMT-Cashmere series

Product highlights description

The green product of Hangzhou Smart Cashmere Co.,Ltd. is "coarse combed tatting blended cashmere fabric", which mainly consists of sheep hair containing more than 30% cashmere, cashmere blended products, or 100% pure cashmere fabric products. The raw material comes from the wool layer or down layer on the body of goats or sheep, which is sheared and combed, and then washed to obtain wool. New raw materials must provide a "Animal Quarantine Certificate" before entering the company for use. Our company mainly processes colorless velvet and wool into fabrics through spinning, weaving, and dyeing processes, providing fabrics for clothing. Due to the high attention paid by the company's senior management to green products, the safety of our newly produced products meets the GB 18401 standard of the National Basic Safety Technical Specification for Textile Products. The formaldehyde content, pH value, odor, and decomposable carcinogenic aromatic amine fuel are all qualified or not detected. This reflects our company's concept of being responsible to consumers.

In summary, Saint Mart's green product "coarse combed tatting blended cashmere fabric" is a safe and reliable product. At the same time, due to its elegant luster, smooth and soft texture, and high-end atmosphere, it gives people a beautiful enjoyment.

Green Product Manufacturing and Standardization Work

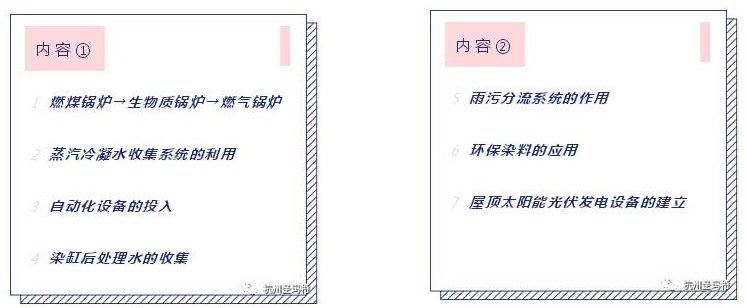

In recent years, the company has strictly implemented national policies on carbon neutrality and carbon emissions, and actively carried out green production and cleaner production:

At the same time, the company has also done a lot of work in conjunction with textile standardization work. Firstly, the actual production process strictly follows the industry standards for wool textile products and the EU, US, and Japanese standards for exported products, and has a "White List" certification certificate for exports to Japan. Secondly, our company actively responded to the call of the Zhejiang Provincial Government for "Made in Zhejiang" and drafted the group standard for "Coarse Combed Imitation Cashmere Pure Wool Products" in early 2018, which was passed and implemented at the end of the year; Third, actively participated in the textile standardization work of Zhejiang Province, and was awarded the title of "Excellent Unit of Textile Standardization Work of Zhejiang Province". Wang Qiushi, the general manager of the company, was awarded the title of "exemplary individual of Textile Standardization Work of Zhejiang Province", and was employed as a member of the cashmere products sub technical committee of the National Technical Committee of Textile Standardization.

The company has successively passed ISO9001 quality management system, ISO5001 energy management system, ISO14001 environmental management system, and ISO45001 occupational health management system certifications. The first round of clean production audit work was officially launched in June 2011, and so far, three rounds of clean production acceptance have been passed. In 2019, the company was awarded the "Made in Zhejiang" certification certificate and the title of "National High tech Enterprise".